Top Six Tips on Weighing up MIG Gun Consumables

When deciding on what brand of MIG gun to purchase, there is a lot more to consider than just the characteristics of the gun itself.

Experience shows that consumables – the tips and nozzles – can make upwards of two-thirds the actual cost of a MIG gun over its lifespan. Those costs can further skyrocket when you think about the lost downtime in switching over parts, and scrambling with malfunctions due to contact tip failure. This downtime is more often than not the result of poor quality consumables. Add that to the inventory and management costs for the large number of spare parts operators need to keep on hand to deal with the frequent consumable changes.

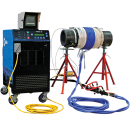

Together, these arguments make a strong case for thinking about the consumables available for a MIG gun as much as the gun itself. Here are our top six tips on weighing up consumables, and why the Bernard MIG Gun and its Centrefire range is an ideal solution.

1. Look for heavy duty

Although some tips may be cheaper, they may not necessarily be designed for heavy-duty commercial use, and can wear out more quickly. As a result, welders need to replace them frequently, and operators end up spending more in the long run buying additional parts, even if unit costs are cheaper. Centrefire tips, however, have been designed to last an average of three times longer than other tips, on both heavy-duty and light-duty commercial jobs.

2. Test how to replace the tips

Many standard tips need to be replaced using pliers. It’s not uncommon to see welders frequently stopping their work to wrestle with pliers to replace the tips. Centrefire tips are non-threaded, and stay in place by hand tightening the nozzle. The result is less downtime, as welders can easily replace the tips by hand, and get back to the job much faster.

3. See if you can rotate the tip

The other downfall of threaded tips is that they stay in a fixed position. This causes them to wear more in one area over time, reducing the tip life. Centrefire tips can rotate 360 degrees, meaning welders can create new wear surfaces and extend their life even further.

4. Check if the tips have a habit of staying centred

Without the proper reinforcements, competitive tips can move easily within the nozzle. The result is an uneven gas flow, poor arc, and reduced weld quality. This can lead to more rework, and less arc time. Alternatively, the Centrefire tips and nozzles remain locked in place, even after hard use, leading to better weld consistency.

5. Look for high quality machining.

If you could dissect a tip, you would see that poor machining leads to coarse channels for the wire. You can almost guarantee that MIG guns that come with cheaper consumables cost less because the manufacturer has taken shortcuts in the machining process. The coarser pathways can cause slower and inconsistent wire feeds, which then chews up the wire. Centrefire tips are machined to the highest quality, with a smoother channel to carry the wire, resulting in less wear on the tip and a more consistent weld.

6. Check for a quality diffuser on the nozzle

Lower quality nozzles with poor diffusers have more turbulent and less consistent gas coverage. As a result, oxidisation and contamination can creep into the weld, leading to poor results, and the need for rework. Centrefire nozzles and diffusers have a smooth and concentrated shielding gas flow, greatly reducing this oxidisation and contamination.

In addition to the quality range of Centrefire consumables, the Bernard MIG gun on its own is a great option for welders. Its neck offers fixed, rotatable and multiple length options, making out-of-position welding much easier. Operators can change over the neck without any tools, further decreasing their downtime.

The trigger has been designed and built to last more than 1 million cycles, and offers numerous easy-to-change options. Its jump liner is replaced only in the most commonly worn areas, which can be easily and accurately done by the operator, reducing the amount of time a gun goes offline.

Check out the full range of Bernard MIG guns and consumables

Date: June 13th, 2017