MIG Industrial

-

Dimension 650 with ArcReach

-

XMT 350 FieldPro with ArcReach

-

XMT 350 MPa

-

XMT 450

-

XMT 450 MPa

-

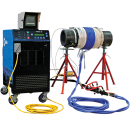

PipeWorx Welding System

Selection Chart

| Product | Process | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stick | DC TIG | High Freq | Lift Arc | MIG | FC | Pulse | Low OCV | CAC-A | Weldable Materials |

Welding Output Range |

Input Voltage | Generator Power Required | Typical Applications | ||

| Dimension 650 with ArcReach |

|

|

|

|

|

3/8” ½” (9.5mm-13mm) |

Steel, Aluminium, Stainless |

15 - 815 A CC 10 - 650 A CV |

415 V 3 Phase |

34 kVA |

Construction, |

||||

| XMT 350 FieldPro with ArcReach |

|

|

|

|

|

1/4" (6mm) |

Steel, Aluminium, Stainless |

5 - 426 A CC 10 - 38 V CV |

415 V 3 Phase |

14.2 kVA |

Construction, Shipbuilding, Fabrication, Pipe Spooling |

||||

| XMT 350 MPa |

|

|

|

|

|

|

|

1/4" (6mm) |

Steel, Aluminium, Stainless |

15 - 425 A CC 10 - 38 A CV |

415 V 3 Phase |

14.2 kVA |

Construction, Marine, Maintenance |

||

| XMT 450 |

|

|

|

|

|

Opt |

|

3/8" (9.5mm) |

Steel, Aluminium, Stainless |

15 - 600 A CC 10 - 38 V CV |

415 V 3 Phase |

22 kVA |

Construction, Fabrication, Mining, Maintenance |

||

| XMT 450 MPa |

|

|

|

|

|

|

|

3/8" (9.5mm) |

Steel, Aluminium, Stainless |

15 - 600 A CC 10 - 38 V CV |

415 V 3 Phase |

22 kVA |

Construction, Fabrication, Mining, Maintenance |

||

| PipeWorx Welding System |

|

|

|

|

|

|

|

Opt | 3/8" (9.5mm) |

Steel, Stainless |

40 - 350 A CC 10 - 44 V CV |

415 V 3 Phase |

20 kVA |

Pipeline, Pipe Spooling |

|

|

Capability |

|||||||||||||||

WIA offers a range of high quality and reliable industrial MIG welders from Miller.

Miller’s range of industrial MIG welders is designed to handle the most demanding industrial applications.

The Miller industrial MIG equipment range includes the Deltaweld 602, XMT 350, XMT 350MPa, XMT 450, Dimension 562 and the Dimension 812.

All Miller MIG welders undergo stringent quality testing before ever leaving the factory, ensuring that every Miller industrial MIG welder delivers on both reliability and durability.